Foam Cleaning of Air Cooled condenser, Fin Fan Coolers

Foam cleaning is an effective use of technology for cleaning systems. It is a perfect solution and gives good results for all the industry requirement.

Foam Cleaning service can save your plant millions in production losses. Dirty fin fans reduce the cooling efficiency of heat exchangers. Clogged, blocked fin fans drive production costs up. If a unit is cooling at a slower rate, it has a dramatic effect on your production and consequently on your profits! Our low pressure, high volume foam cleaning process removes dirt, debris and hydrocarbons safely and thoroughly. Your cooling system begins performing at an optimal level and the results equal multiple financial benefits. Clean exchangers after a foam cleaning process result in less energy requirements allowing fans to be turned off, run less or more slowly. Our specialized foam cleaning process returns your equipment performance to original OEM ratings and allows you to produce at optimal levels. We ensure that the best appliances are delivered to you with the right kind of support needed.

- Safe Work

- Low pressure high volume coverage will not damage fins

- Eco-friendly product

- AC frequency used in the exciting coil

- Quick response and quick set-up time

- Easy scheduling during outages, turnarounds or during production on-line operation

- Thoroughly cleans top-to-bottom of exchanger

- No residue left behind minimize dirty cycle start up

- Purpose-built application equipment

- Turn-Key Service Minimal Support Required

- Fast, On-Time Completion

- 24/7 Management by Trained & Certified Technicians

VMAX Foam Cleaning service results:

- Improved cooling performance and unit efficiency

- Increased production

- Extended component life

- Reduced maintenance costs

- No production loss with online cleaning

- Zero damage to fins

- Removes all debris and corrosive elements

- pH balanced cleaning formula

- Lower energy consumption and costs

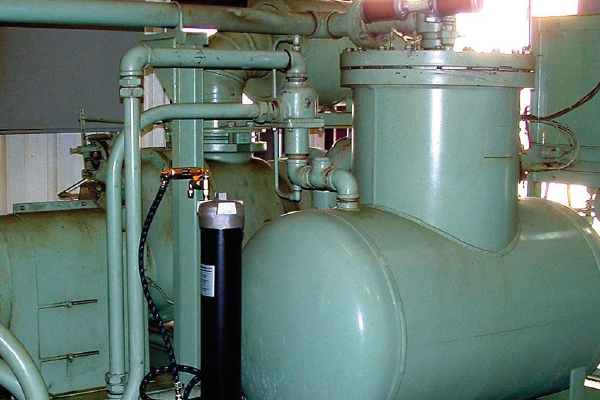

High pressure Hydro jet cleaning of Boilers, Condenser, Heat Exchanger, Coolers etc

High-pressure hydro jet cleaning:

The high-pressure cleaner is also known as a high-pressure washer which is used for hundreds of cleaning applications worldwide. Vmax high-pressure hydro cleaning designed and manufactured with the latest European technology with superficial quality materials.

How does high-pressure hydro jet cleaning work?

It is done through an opening called a cleanout which is used to clean all the dust and debris once and for all. Our every plumbing system is designed to carry out the waste and debris is cleared out by the high-pressure hydro jet cleaning work.

What are the benefits of high-pressure cleaning?

Thes high-pressure cleaning jet can easily cut through the most stubborn roots and clear out the debris any amount of root penetration is cause for serious concern. Hydro-jet cleaning equipment completely cleans off all holding tanks with no ill effects to the vehicle or the environment.

Mechanical cleaning of Condenser, Heat exchanger Tubes.

Mechanical cleaning:

There are different source of cleaning and mechanical cleaning is one among them. Mechanical cleaning systems are used to remove contaminants of work surface by propelling abrasive materials like airless centrifugal blast blade- or vane-type wheels; compressed air, direct-pressure dry blast nozzle systems; wet or dry blast nozzle systems.

Chemical Cleaning of Condenser, Heat Exchanger, Cooler tubes

Chemcial cleaning:

Chemical cleaning uses a wide range of services where it is the procedure for field cleaning of the piping systems especially Steam lines inlet for Turbines and Steam Drums. These pipelines after cleaning shall be free from hydrocarbons, greases, oils, rust, scale, and other impurities. In chemical cleaning, chemicals are used to loosen the hard deposits from process equipment or piping surfaces and removed.

Oil flushing and purification

Oil flush and purification:

Oil Purification Systems used for purification, reconditioning, cleaning or reclaiming of oils. We make you help in maintaining the equipment. We can install one piece of equipment or else install a whole team to manage all your filtration technology everyday.The goals remain the same Cleaner fluid, longer tool life, higher quality parts.